HEAD GASKETS: Are they really a Subaru nightmare?

1 JUL 2025 - Jeff Willis

Today’s topic is head gaskets, and the stigma associated with the Subaru EJ engines, and why they are a known sleep paralysis demon in the Subaru world and why all Subaru owners want to avoid them. Well, any owner of a gas combustion engine never wants a blown head gasket simply because it is one of those repairs that is quite expensive, due to how labor-intensive it is to perform the process and why it particularly sucks on a horizontally opposed engine such as the Subaru.

WHAT IS A HEAD GASKET?

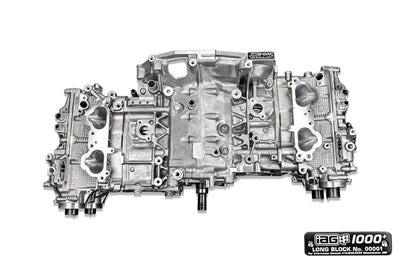

In technical terms, your engine as a whole is called a long block.

(Long Block)

IAG 1000+ EJ25 Closed Deck Long Block w/Stage 5 Heads 2004-2007 STI

Now many of you know what a long block is. This is the engine assembled with the heads and short block. A short block is the bottom half of your engine that consists of the crankshaft, the connecting rods, pistons, bearings, and main caps. Aka the key guts of the engine.

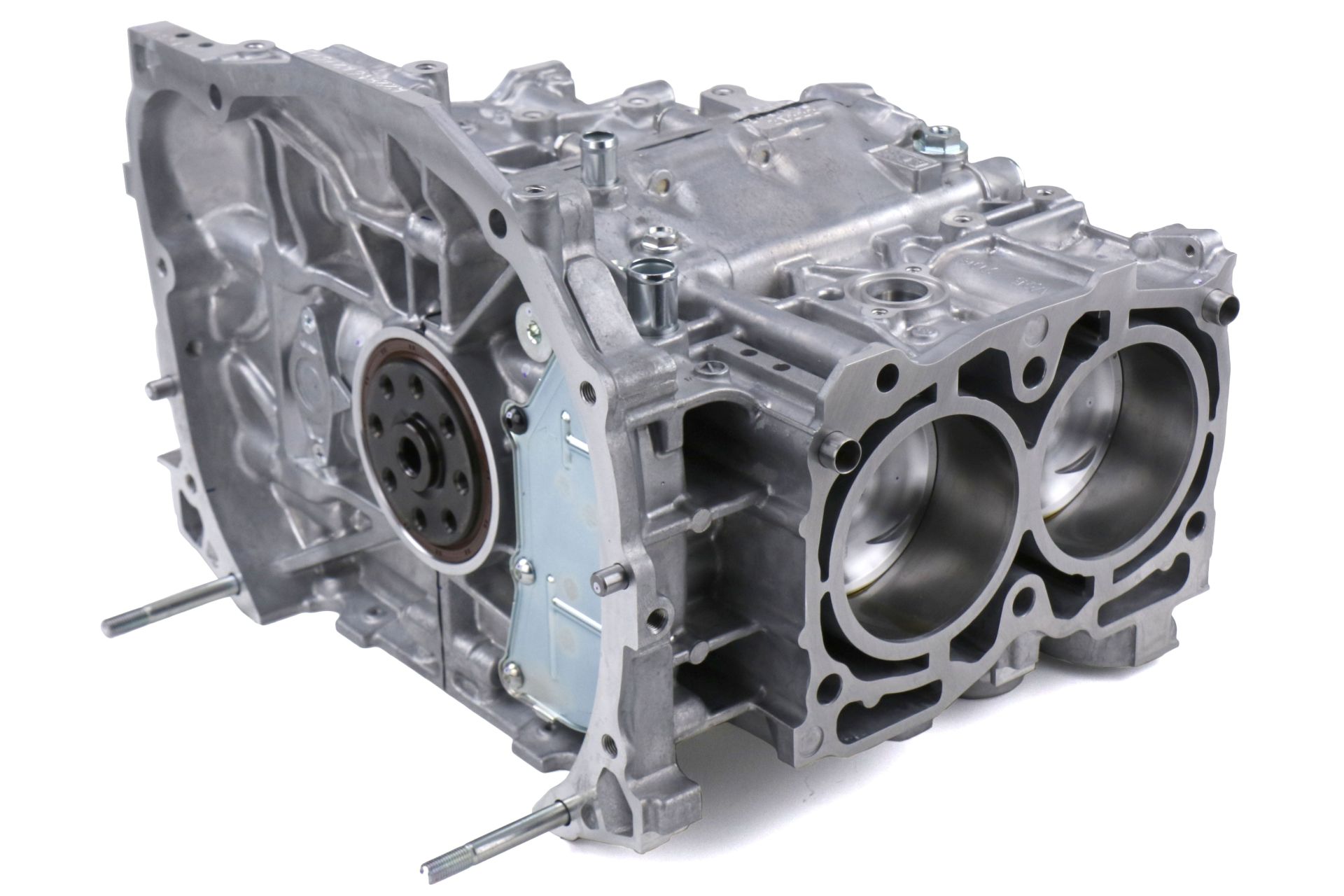

(Short Block)

Subaru OEM STI Type RA Short Block 2018 Type RA 2019-2021 STI

Between the short block and the heads is sealed by the head gaskets. Head gaskets are usually made using multi-layered steel materials, and there are aftermarket head gaskets made in different thicknesses depending on what type of machine work your short block received, and some are made using different materials and coatings depending on how your build is blueprinted.

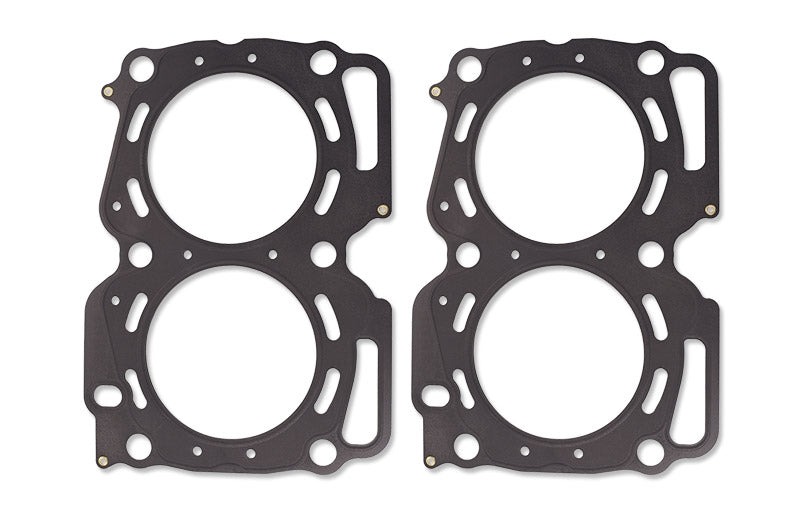

Subaru OEM Head Gasket 2002-2005 WRX

Yes, this thin gasket carries so much responsibility in the overall welfare of your engine, and here’s why. Your heads, as well as your short block have water passages that run throughout the engine block, as well as the heads to keep them cool during operation. One of the major functions of the head gasket, aside from the obvious, is to provide a proper seal. However, head gaskets prevent the coolant from leaking outside of those coolant passages and coolant jackets and into your cylinders.

Furthermore, head gaskets seal the compression your cylinders make with the valve chamber of your heads as well. We will talk about the symptoms of a bad head gasket, but if you lose compression after your car overheats, you could very well have a blown head gasket.

WHAT HAPPENS WHEN YOU BLOW A HEAD GASKET? WHY DOES IT HAPPEN?

Generally, blown head gaskets are caused by overheating. And this is across the board with all gas combustion engines. A failed water pump, a stuck closed thermostat, or a leaking coolant hose can all lead to overheating. What is crucial is how aware you are as a driver to shut the engine down before any major damage happens (blown head gasket). Because most everyday people who commute to work, run errands, etc. will drive their cars even if the temp needle on the dash is pegged.

All cars in general will have a normal operating temperature which is anywhere from 185-205°F. 195 degrees are average for most cars with all cooling system components working as they should. This means no leaks in the coolant system. Your fan clutch is working well if you have a belt-driven fan. Or your electric fans start kicking on as soon as temps start going over 185°F. However, there are other contributing factors that can lead to either overheating, or your engine running hotter than average even if you can confirm that your water pump and cooling fans work, and if you can confirm that you have no leaks. Most people do not realize that the ½ inch of space between your radiator, and air conditioning condenser collects dirt and dust over time and can block the air flow going to your radiator. So, there are things you can do such as getting a pressure washer and holding it a few feet away to where you’re not blasting the radiator or AC condenser fins shut, but just enough to where it can blow out any leaves, dirt, dust, and rocks to clear that area.

So how does a head gasket fail then? On the topic of overheating, you reach a point where there’s no going back. Your heads are made from aluminum, and if your engine gets hot enough, those heads will warp. They will warp enough by bowing, or bending, and creating just enough space where the pressure can push coolant into your cylinders.

By the time this happens, your engine can lose compression and there is a major loss of power. If you suspect that you have blown a head gasket in your Subaru, stop the engine from running so that you do not cause further damage to your motor.

One of the biggest dangers with a blown head gasket is the coolant filling up your cylinder where your gasket had let go. Coolant is water-based, and you cannot have water in your cylinders because this is a space reserved for gasoline and combustion. If you have water going into your combustion chamber, you will have billowing white smoke coming out of the exhaust.

The other danger is that the coolant will wash through the piston rings, and into your oil. Oil and water do not mix so immediately, your oil loses its lubricating properties, and you risk damaging your rod and crankshaft bearings if you keep driving the car. Now when coolant does make it into the cylinder chamber, and through your piston rings, the obvious sign of a blown head gasket is that the oil turns into a frothy chocolate milk consistency. You will see it on the dipstick, but the most common sign is spotting that frothy oil and water mixture under your oil cap:

This will be the obvious sign because the coolant has already mixed with your oil. Your oil has started to foam; things need to come apart.

WHY HEAD GASKET REPLACEMENTS ARE SO EXPENSIVE – ESPECIALLY FOR A SUBARU

Head gasket replacement repairs are performed not by just one mechanic. And it needs to be done right, and right the first time. There are no cutting corners with this job. There is no trying to find the cheapest mechanic on FB marketplace that you can put your faith into. Do it right once, or you will be paying for it twice.

The reason why head gasket replacements are so labor-intensive is because obviously you need to remove your heads. But you must remove every component, accessory, vacuum hose, sensor, intake manifold, turbo, exhaust manifold before you even get to remove the valve covers. Then you must break down tall of the radiator hoses, serpentine belts, timing belt, and all of the timing belt accessories. Once the valve covers are off you need to remove the camshaft sprockets, the cam caps, and the cam shafts so that you have access to the head studs.

ARP 11mm Head Studs 2002-2014 WRX / 2004-2021 STI

This is the standard procedure on any vehicle that needs a head gasket replacement. Now why it is a little more complicated on a Subaru as opposed to an Evo where you can access everything from the top of the motor because of the inline-4 design, is because Subarus like Porsche, are horizontally opposed. Aka flat-four engines. This means that there is maybe 2 inches of space between the frame of the vehicle, and the valve covers on each side. There is no room, the motor must be removed.

With the engine mounted on an engine stand, any experienced mechanic can now have much easier access to everything on the motor and can tilt the motor in such a way to either remove or torque down the head studs which are the critical hardware for a successful head gasket replacement.

After all of the mentioned components are broken down, and the heads can be separated from the short block, the heads need to be resurfaced at a proper machine shop. Resurfacing the heads is the procedure there the surface is decked, grinded, or sanded down to have a flat mounting surface again. The heads must be 110% flat to maintain a proper seal. And a machine shop will thoroughly clean your heads of any debris by hot tanking them, and they will make sure your valves are making a proper seal and inspect other components to make sure they are working correctly so that the heads are ready to be re-installed on your short block.

Now depending on how much the heads had to be decked, sometimes a thicker head gasket must be used to make sure that a proper seal and compression are maintained. And head studs are very critical. You must use new head studs when re-installing heads unless you are running ARP head studs which 90% of people will do because since you’re already spending a small fortune for the job to be done right, what’s another $240?

UPGRADING YOUR HEAD GASKETS DURING THE JOB

Now this is the time to upgrade your head gaskets. Here is a factory EJ25 head gasket:

Subaru OEM EJ25 Head Gasket 2004-2007 STI.

With Subaru, there is never a one-size-fits-all type of head gasket. Because there are varying years, and there are varying builds. You either want to keep things relatively stock and just need to get your car back on the road, or you want to get a thicker head gasket for a built closed-deck motor. And then there are AVCS heads. You just need to make sure that you are getting the right head gaskets for your year, make, and model. Or if you are building a motor, your engine builder should know what thickness of head gaskets they want you to get. And there are different types of head gaskets to suit larger head studs. It can be a rabbit hole for sure.

At the very least, you should go with a multi-layer steel head gasket (MLS). Look at these GrimmSpeed units for example:

GrimmSpeed 1.5mm Head Gasket Set 2008-2021 STI

These are around the OEM thickness range, but they feature multi-layer steel technology with other features such as a nitrile rubberized coating on the top layer, and they also have slightly enlarged bolt holes to accommodate 13mm head studs.

A multi-layer-steel head gasket provides the right seal needed to contain yet separate the pressure from the coolant running through the water passages, the compression between the cylinders and the valve chamber, while containing the pressure from the exhaust gases as well. All of this is not possible without the correct torque settings on the head studs. Your head studs typically go through 3 sets of torque sequences. For example, some motors will want you to do the primary torque sequence beginning at 85 ft/lbs. Then moving to 110 ft/lbs. Then a final torque on your torque wrench at 120 ft/lbs.

Another area you must pay attention to, and your mechanic/builder should know, is the bore size of your head gaskets. Head gaskets can lead to engine failure because as water enters the combustion chamber, it eliminates the lubrication from the oil, therefore, your cylinder walls get scratched, and they must be honed out to accommodate your new piston size. The bore size of your cylinders MUST match your head gaskets.

This is an example of IAG’s head gaskets made for large head studs with a larger bore:

IAG Performance 100mm Head Gasket Set For 14mm Head Studs 2006-2014 WRX / 2004-2021 STI

THIS SOUNDS LIKE A GIANT HOLE IN THE BANK ACCOUNT. HOW DO I PREVENT THIS?

The only way to reduce the chances of failed head gaskets is to have more situational awareness on your cooling system especially since we are now in prime summertime, and temps throughout the US will hit triple digits. Every vehicle manufacturer has a recommended coolant flush interval, and it can range anywhere from 60 to 90k miles. Again, coolant is water based and when coolant is constantly running through iron and aluminum channels, it is normal for the coolant to become dirty over time with deposits, rust, all of which can cause buildup in your hoses. A fresh coolant flush every 50k miles ensures that there is no major debris in the channels of the engine block and throughout your hoses.

You can upgrade to an all-aluminum radiator that will improve your overall coolant efficiency. As a matter of fact, let’s make a checklist of what you can do to maximize your coolant efficiency:

CLICK HERE FOR ALL-ALUMINUM RADIATORS

This will be the last radiator you will buy because they don’t have plastic end-tanks that will crack after years of continuous heat cycles. Plus, many all-aluminum units are slightly thicker for better cooling efficiency.

CLICK HERE FOR ALL THERMOSTATS

If you overheated and can confirm that your head gaskets are fine because there is no excessive smoking and you don’t have frothy chocolate milk under your oil cap or dipstick, more than likely it will be a stuck thermostat. A stuck open thermostat allows the coolant to flow throughout the motor from the get-go so your engine will over cool while driving and overheat when stuck in traffic. A stock closed thermostat will not open after hitting the pre-determined heat range which will not allow the coolant to flow throughout the engine thus, causing overheating. The thermostats are cheap enough that you should ALWAYS replace if you ever find yourself in a position where you are draining your coolant for any maintenance or upgrades as a preventative measure.

CLICK HERE TO UPGRADE TO SILICONE RADIATOR HOSES

Yes, OEM rubber hoses that leak are one of the common leads to failed head gaskets in Subarus. We often discuss in other blogs how OEM Subaru radiator hoses are known to get weak with time. And after many heat cycles, the OEM hoses will expand under pressure enough to tear the internal fibers which will allow the hoses to further expand, causing a tear at the mounting clamps, or contact the cooling fan. Silicone units are much stronger, won’t expand under pressure, and improve your overall cooling efficiency.

WATCH YOUR TEMP NEEDLE

Yes, during summer if you are ever in stop-and-go traffic, at a traffic jam, or at a drove-through always periodically look at your temp needle. When driving on a long ascending climb it is normal for your temp needle to go up a little. In the summer it is normal for your temp needle to move just a bit on the hotter side especially in triple digits.

However, in normal driving situations you see your temp needle get to the ¾ mark, that means that your coolant temps have exceeded 200°F+, and you need to watch that needle closely and prevent your engine from ever getting into the red. If you start getting near the red, pull over to a safe location, shut the motor off and let the engine cool, and see what’s going on.

Most importantly, NEVER remove a radiator cap if the engine is still hot otherwise, you are going to blast boiling hot coolant all over you sending you to the hospital. When your engine is cool, make sure that your coolant is topped off at the radiator, and at your expansion tank. Also make sure that your engine has an appropriate amount of oil as well.

THE THING IS

Are blown head gaskets a prevalent issue for Subaru engines? Not exactly. Now according to google, these issues were more prevalent in non-turbo models, and it was a problem for WRX models when “coating” wore off the head gaskets to cause a leak.

The stigma is just how massive of a repair it will be if you should ever happen to experience blown head gaskets on a Subaru. The motor needs to come out. The engine essentially needs to get torn down without removing pistons, rods, and crankshaft. But if you needed to they are very accessible at that point.

The key to preventing blown head gaskets is to make sure your cooling system components are all in good working order, make sure your Subaru is properly maintained, and don’t drive the car like you’re in some perpetual race.

What we highly recommend in the unfortunate event of blown head gaskets are upgraded head studs to avoid the chance of lifting your heads. As well as a good multi-layer steel head gasket set. With these upgrades the engine can now withstand a little more performance, while providing extra protection against another head gasket failure.

For now, if you have a properly running Subaru, just make sure you know the overall welfare of your cooling system components. Upgrade them if need be. And don’t allow your temp needle to ever get too high.

CLICK HERE FOR ALL HEAD GASKETS

CLICK HERE FOR HEAD STUDS